What Is Proof Load?

The compliance testing for couplers consist of 2 tests.

i) Tensile Strength Test- Loading to failure to determine the maximum force

ii) Slip Test/ Permanent Elongation- To capture the displacement in the thread under service loads

Before carrying out a tensile strength test, the slip test has to be carried out according to ISO 15835:2009 by stressing the coupler to 0.6fy. After the coupled bar has been loaded to 0.6fy, the load is removed and the residual displacement is measured to ensure that excessive displacement will not result in serviceability problems. This slip limit varies from standard to standard, but the limit in ISO 15835:2009 is 0.10mm.

A proof load represents a load level above the likely service stresses, but below the design yield of the rebar. When loaded to 0.75fy, it will ensure that every connection installed can achieve an acceptable safety factor against failure. A side effect of this proof loading is stress relief of the cold work done during production. This stress relief then reduces the amount of permanent elongation in the system, giving the final structure a larger safety factor against serviceability limits.

The Importance Of Proof Loaded Threading System

With proof loading, we will be able to determine beforehand and assure the threading system meets the requirements. At Leviat, proof loading facility is available upon request, every prepared bar end will undergo a proof load testing prior leaving the production factory.

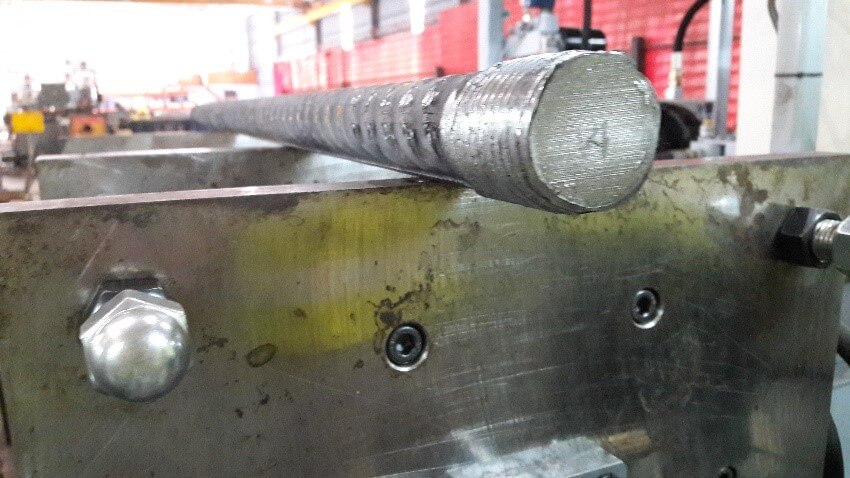

A positive indication ‘A’ will be stamped on the rebar to indicate that proof load has been carried out.

To fulfil the quality assurance of MRT Line 1 & 2 projects in Malaysia and LTA requirements in Singapore, Leviat has managed to provide proof loading for each rebar thread, to check the embrittlement of the threads and control the slip. It is our part of the quality control procedure developed to reassure good quality of threads before we supply it to each project site. After all, a good quality connection between rebars is not just settled by the quality of the coupler but also equally by the quality of the threading on rebars.